Key Takeaways:

- A feeder is a device that supplies materials or substances to a processing system, while a distributor is a device that distributes materials or substances from a single source to multiple outlets.

- The functions of a feeder include controlling the flow rate, preventing material segregation, and providing consistent material distribution, while the functions of a distributor include dividing materials evenly, redirecting material flow, and controlling outlet pressure.

- Both feeders and distributors play crucial roles in material handling and processing systems, but their purposes, usage, types, design, installation, operation, maintenance, cost, and applications differ significantly.

What is a Feeder?

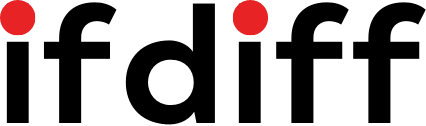

A Feeder in electrical systems is a specific type of conductor that carries electrical energy from one point to another within a distribution network or system. It plays a crucial role in the safe and efficient transmission of electricity.

Feeder components typically include conductors, protective devices, and monitoring equipment. These components work together to ensure a steady flow of power while safeguarding the system from overloads and faults.

The design of a Feeder must consider factors such as voltage levels, current ratings, and load requirements to maintain a stable distribution of electricity.

With different configurations like radial, loop, or network feeders, each Feeder type is tailored to meet specific operational needs.

Proper maintenance and periodic inspections of Feeders are essential to prevent potential disruptions and ensure continuous power supply.

What is a Distributor?

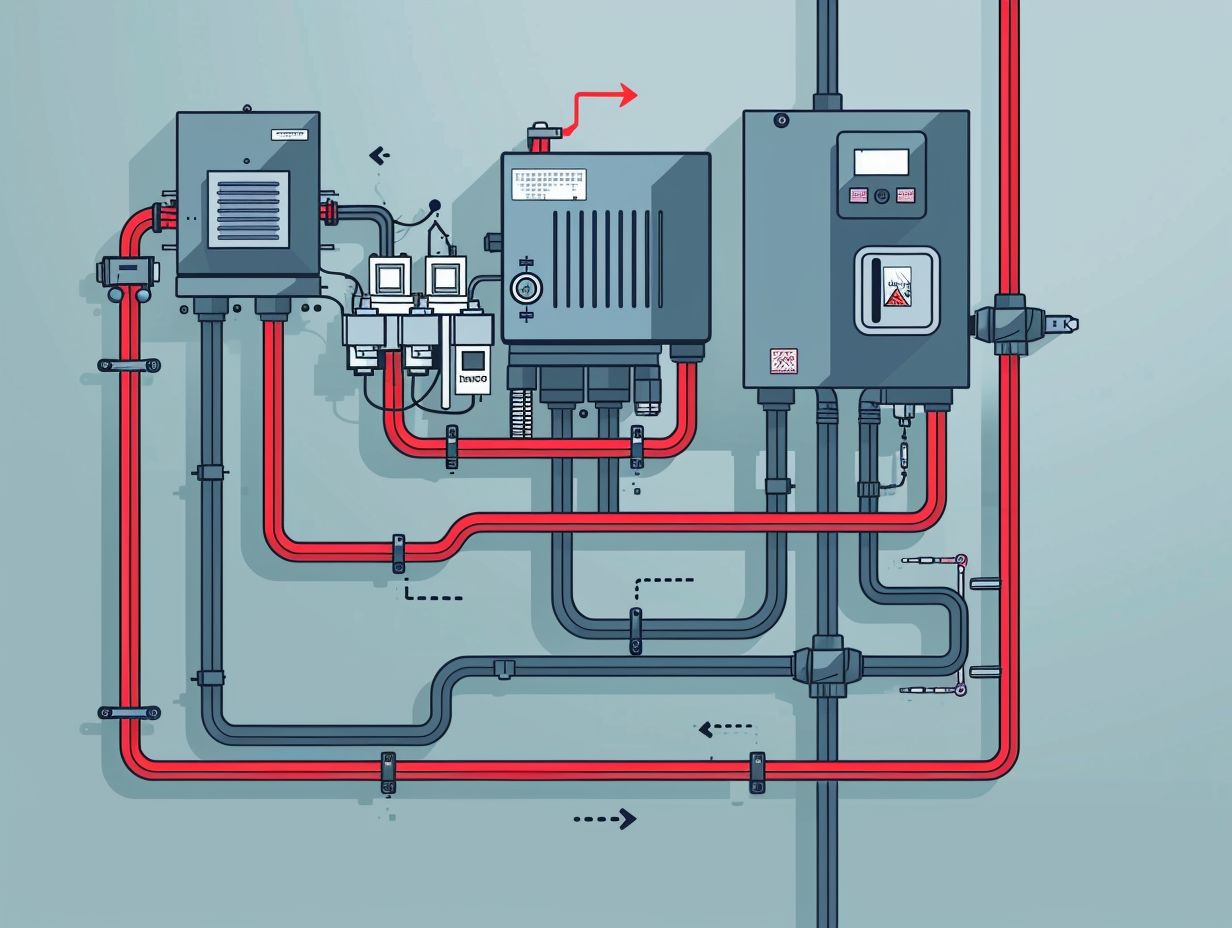

A Distributor in electrical engineering refers to a component responsible for dividing electricity from a Feeder into multiple branches to supply various loads or consumers efficiently.

The key role of a Distributor lies in its ability to manage the distribution of electrical power across different circuits or equipment, ensuring a steady and balanced flow of electricity.

This component acts as a crucial intermediary that receives power from the Feeder and separates it into distinct branches, enabling the electricity to reach specific destinations effectively.

It plays a vital role in preventing overload situations by evenly spreading out the power supply.

Distributors come in various types, such as busbar systems, circuit breaker panels, or fuseboxes, each serving a specific purpose in electrical distribution networks.

These installations are designed to handle different voltage levels and current capacities to suit specific application requirements.

What are the Functions of a Feeder?

Feeder functions include transmitting electrical energy at specified voltage magnitudes, utilizing conductors with suitable current carrying capacities to maintain safe operation and efficient power distribution.

One crucial aspect of Feeder operation is the voltage management, where the system ensures that the transmitted energy remains within the designated voltage limits to prevent equipment damage and ensure compatibility with end-user devices.

By carefully choosing the appropriate conductor selection criteria, like wire gauge and material, Feeders can effectively handle the flow of electricity without overheating or overloading.

Feeders play a significant role in minimizing losses by efficiently delivering electricity to load centers, reducing wastage and optimizing energy distribution.

What are the Functions of a Distributor?

Distributors perform functions such as reducing voltage drops by distributing electricity effectively, enabling tapping points for branching circuits or equipment connections within an electrical system.

One of the key functions of Distributors is voltage management, where they ensure that the voltage levels are appropriately distributed to different parts of the electrical network.

By regulating and stabilizing voltage, Distributors help in preventing power surges and protecting sensitive equipment from potential damage.

In addition, Distributors play a crucial role in balancing the load across various circuits, ensuring that no single circuit is overloaded.

Similarities Between a Feeder and a Distributor

Both Feeders and Distributors are essential components of electrical systems, responsible for transmitting and distributing electricity to different parts of the network efficiently.

Feeders and Distributors play crucial roles in power transmission and distribution, ensuring a steady flow of electricity throughout the network.

Feeders are designed to carry a significant amount of power over long distances, while Distributors serve to divide and direct this power to various loads efficiently.

They both work in tandem to maintain a balanced and reliable electrical system, minimizing the risk of overloads and protecting against potential faults.

Differences Between a Feeder and a Distributor

The differences between a Feeder and a Distributor lie in their distinct purposes, usages, types, designs, installation methods, operation procedures, maintenance requirements, costs, and applications in electrical systems.

Feeders are primarily responsible for carrying power from the main electrical panels to the subpanels or branch circuits, ensuring a continuous flow of electricity along the designated path.

On the other hand, Distributors focus on distributing power to various loads or devices within a specific area or zone, splitting the electrical supply into multiple branches.

In terms of types, Feeders can be categorized into main, sub-main, and branch feeders, depending on their location and capacity requirements, while Distributors are often classified as panelboards, switchboards, or load centers based on their functions within the electrical system.

Purpose

The primary purpose of a Feeder is to transmit electrical power from a source to distribution points, while a Distributor aims to divide and route electricity from the Feeder to multiple branches or circuits efficiently.

Feeders play a crucial role in electrical systems by carrying power over long distances with minimal loss, ensuring a steady flow of electricity to various distribution points.

They are designed to handle high currents and voltages while maintaining stability and reliability.

In contrast, Distributors act as the intermediary between the Feeder and individual branches, regulating and directing the flow of electricity to specific areas or circuits.

They make use of switches, circuit breakers, and other protective devices to ensure safe and efficient distribution.

Usage

Feeders are primarily used for transmitting bulk power over long distances, while Distributors are deployed for dividing and supplying electricity to various loads or consumers within a localized area.

Feeders play a crucial role in electrical networks by carrying high-voltage electricity from power plants to substations or industrial facilities situated far away.

They ensure that power can be transmitted efficiently with minimal losses over lengthy distances.

On the other hand, Distributors function closer to the end-users, distributing electricity at lower voltages to residential, commercial, or industrial consumers.

Feeders are characterized by their capacity to handle large power loads, operating at high voltages to minimize energy losses during transmission.

In contrast, Distributors are essential for managing the division and delivery of power to individual consumers, ensuring a balanced and stable electricity supply across different areas.

Types

Feeders can be classified into primary, secondary, and tertiary types based on their voltage magnitudes and power transmission capacities, whereas Distributors vary in types such as radial, ring main, and interconnected configurations depending on the distribution network structure.

Primary feeders typically operate at higher voltages and carry a significant amount of power, connecting the main substation to different substations.

Secondary feeders branch off from primary feeders and distribute electricity to specific areas or neighborhoods.

Tertiary feeders are the final step in power distribution, delivering electricity directly to individual consumers.

On the other hand, radial distributors have a single feed or source and supply power to end-users in a linear manner, whereas ring main distributors form a closed loop to ensure redundancy and reliability in case of any faults.

Interconnected distributors connect multiple feeders to enhance system reliability and flexibility in managing power flow.

Design

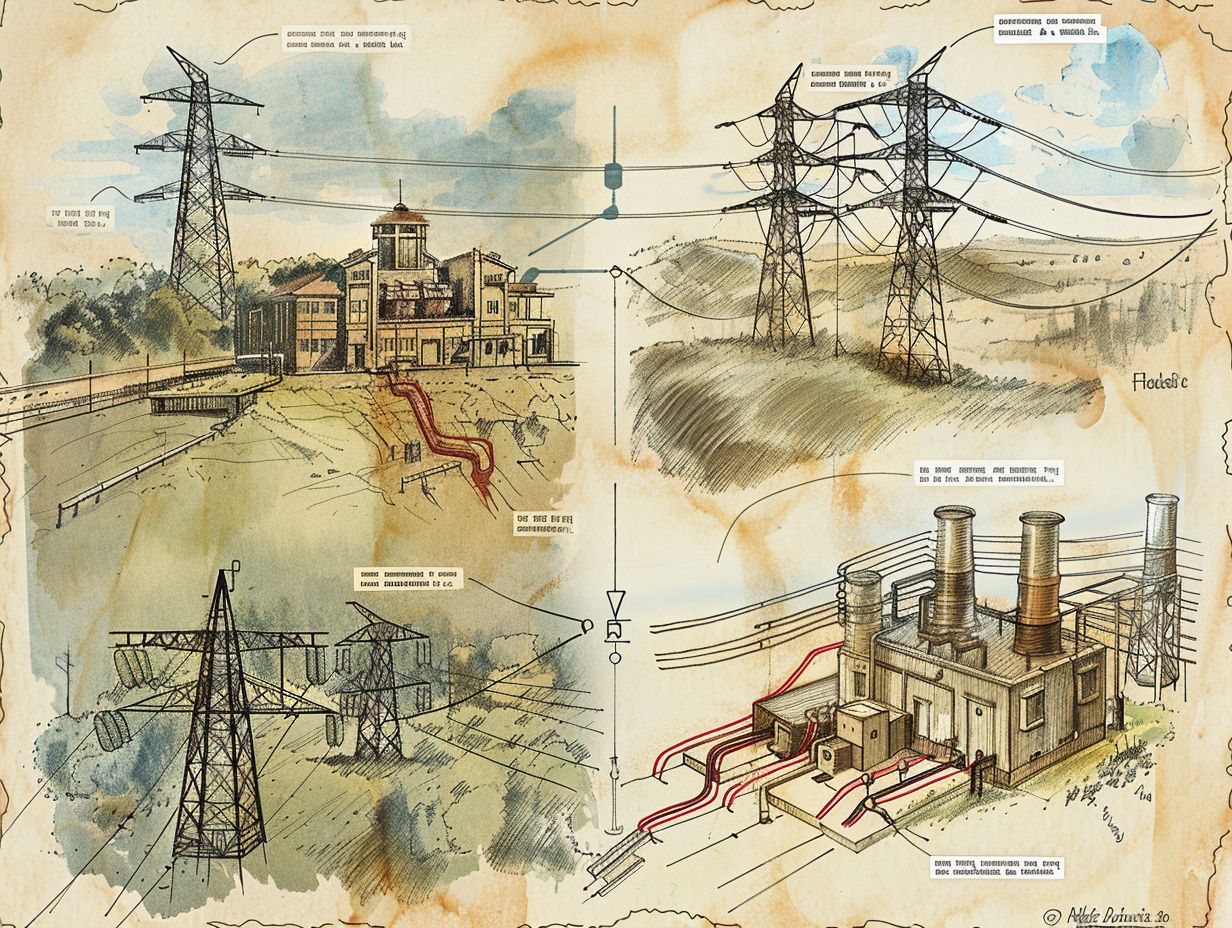

The design of a Feeder focuses on ensuring optimal current carrying capacity, voltage regulation, and safety features for efficient power transmission, while a Distributor’s design emphasizes effective branching, voltage management, and equipment connections for reliable electricity distribution.

For Feeders, it is crucial to consider the current handling capabilities to avoid overload situations that could lead to overheating and system failure.

Voltage regulation mechanisms play a key role in maintaining stable power transmission, ensuring that connected loads receive the required voltage levels without fluctuations.

On the other hand, Distributors are strategically designed to manage voltage drops, especially in systems with long transmission distances.

By incorporating proper distribution transformers and sectionalizing switches, Distributors help in maintaining consistent voltage levels across various branches and connections in an electrical network.

Installation

The installation of a Feeder involves connecting it from the source to distribution points with proper insulation, protection, and routing considerations, while a Distributor’s installation focuses on creating branching connections, tapping points, and load distribution arrangements within an electrical system.

When installing a Feeder, it is crucial to begin by identifying the power source and designing the routing path to the distribution points.

Conduct a thorough assessment to determine the cable size, material, and insulation required based on the load capacity.

Ensure that the Feeder is securely anchored and properly supported along its path to maintain stability and prevent sagging.

- For Distributors, the installation process is centered around setting up branching connections to effectively manage power distribution.

- This involves strategically locating tapping points where connections can be made to accommodate various loads.

- Distributors also require protective measures such as circuit breakers or fuses to safeguard against overloads and short circuits.

Operation

The operation of a Feeder entails transmitting electricity at designated voltage levels, monitoring current flows, and ensuring efficient power transfer, whereas a Distributor’s operation involves managing voltage distribution, load balancing, and equipment connectivity for effective electricity supply.

Feeders play a crucial role in transmitting power from distribution substations to various consumption points, ensuring that electricity reaches users at the required voltage levels.

By monitoring current flows continuously, Feeders can detect fluctuations and promptly address any issues that may impact the stability of the electrical grid.

This monitoring capability allows operators to optimize power transfer efficiency, enhancing the overall reliability of the distribution system.

On the other hand, Distributors are responsible for managing voltage distributions across different sections of the grid.

They balance loads dynamically, ensuring that electricity is distributed evenly to prevent overloading or underutilization of equipment.

By facilitating seamless connections between various electrical devices and systems, Distributors enable a smooth flow of power throughout the network, supporting uninterrupted service for consumers.

Maintenance

The maintenance of a Feeder involves regular inspections, testing for insulation integrity, and addressing any faults or damages to ensure continuous power transmission reliability, while Distributors require maintenance activities such as voltage checks, circuit monitoring, and connection inspections to sustain efficient electricity distribution.

Inspecting Feeders starts with visually examining the insulation for any signs of wear or damage, followed by utilizing specialized equipment like insulation resistance testers to pinpoint any potential faults.

Testing for faults involves simulating various scenarios to identify weak points in the system that could lead to disruptions in power flow. When addressing damages, prompt repair or replacement of components is essential to prevent power outages and maintain a robust electrical infrastructure.

On the other hand, Distributors need voltage checks to ensure that electricity is delivered within the specified range. Circuit monitoring involves analyzing current flows and voltage levels to detect overloads or fluctuations that may indicate potential issues.

Connection inspections focus on verifying the integrity of terminals and conductor joints to maintain a reliable flow of electricity throughout the distribution network.

Cost

The costs associated with Feeders typically include expenses for conductor materials, insulation, protection mechanisms, and installation labor, whereas Distributors’ costs encompass components, branching equipment, tapping points, and maintenance activities required for efficient electricity distribution.

When analyzing the costs of Feeders, one must delve into the specifics of material costs, evaluating the prices of copper, aluminum, or other relevant conductive materials essential for power transmission.

The choice of insulation materials also plays a key role in determining expenses, affecting both initial investments and long-term maintenance outlays.

The incorporation of protective devices like fuses, circuit breakers, or surge suppressors adds to the financial outlay of Feeders.

On the other hand, Distributors necessitate a focus on component costs, including transformers, switches, and meters along with branching equipment such as panels and junction boxes.

Appraising tapping points, which enable diversified power distribution across various circuits, is crucial for understanding the financial commitments associated with Distributors.

Regular maintenance tasks like inspections, repairs, and replacements incur ongoing costs, influencing the overall budget allocated for sustaining efficient electricity dissemination.

Applications

Feeders find applications in long-distance power transmission networks, industrial facilities, commercial buildings, and residential complexes to ensure efficient electricity supply, while Distributors are utilized in local distribution systems, substation connections, equipment power routing, and load balancing scenarios for effective electricity distribution.

Feeders play a crucial role in channeling electricity over vast distances without major power loss, making them essential in supplying energy from power plants to distant areas.

Distributors, on the other hand, are essential for managing the flow of electricity within localized grids, ensuring that power is evenly distributed to different sections.

Feeders are often used in conjunction with transformers to step up or step down voltage levels depending on the transmission requirements, optimizing the transfer of electricity across different voltage levels efficiently.

Frequently Asked Questions

What is the difference between feeder and distributor?

Feeder and distributor are both terms used in the energy industry, specifically in the distribution of electricity. While they may seem similar, there are key differences between the two.

What is a feeder in the energy industry?

A feeder is a section of an electrical distribution network that carries electricity from a substation to a specific location, such as a residential or commercial area. It is responsible for delivering electricity to a smaller area and is connected to a larger power source, such as a substation.

What is a distributor in the energy industry?

A distributor is a company that is responsible for delivering electricity from the feeder to individual customers. They are in charge of maintaining the distribution network, including poles, wires, and transformers, and ensuring that customers receive a reliable supply of electricity.

What is the main difference in their roles?

The main difference between a feeder and distributor is their role in the distribution of electricity. While a feeder carries electricity from a substation to a specific location, a distributor delivers electricity from the feeder to individual customers.

Do both feeders and distributors have the same infrastructure?

No, feeders and distributors have different infrastructure. While a feeder is primarily made up of larger power lines, a distributor’s infrastructure includes smaller power lines and equipment, such as transformers, to deliver electricity to individual customers.

Is there any overlap between the roles of feeders and distributors?

While their roles may seem distinct, there can be some overlap between feeders and distributors. In some cases, a feeder may also act as a distributor and deliver electricity directly to customers. However, this is not always the case and is dependent on the specific distribution network.